Industrial Mixers

Mixing is an integral component of creating a stable emulsion from several mutually soluble or insoluble liquids. Industrial mixers are used in almost all areas — in the food, chemical, fiber, cosmetic, textile industries, as well as for the creation of plastics, detergents, etc. Possessing a sufficiently large power and corresponding design features,mixing devices help to achieve maximum solubility in a viscous liquid, even solid particles of a suspension.

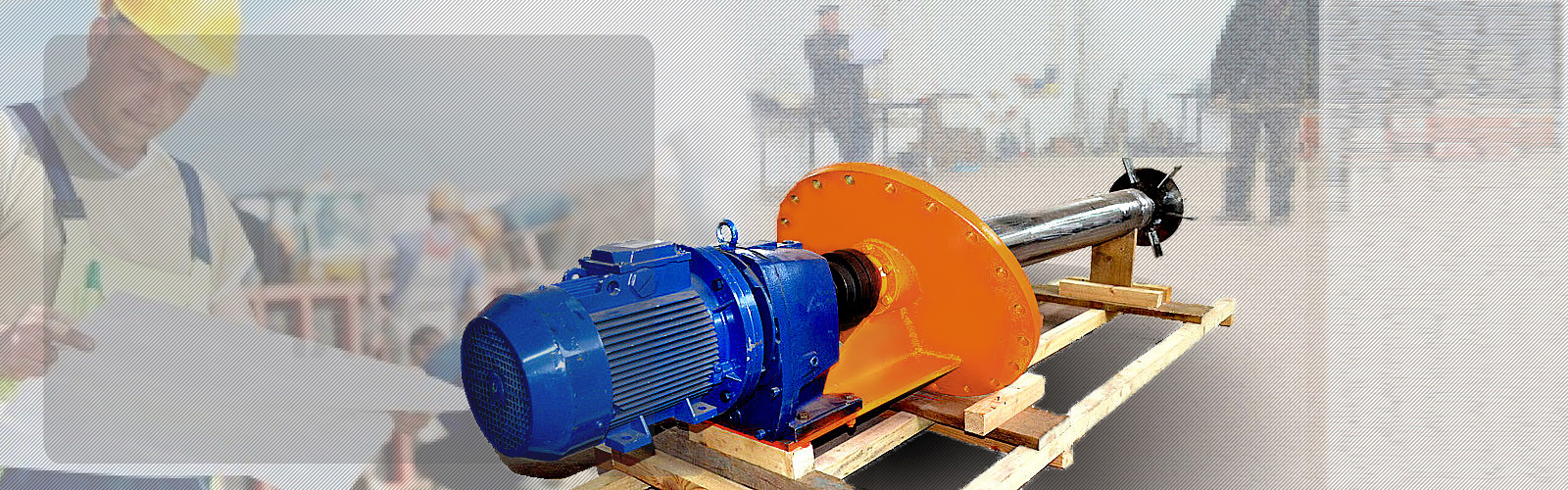

The Tula Mashiny LLC company is a domesticmanufacturer ofmixers of various types — frame, sheet, paddle, milling, turbine, propeller, and also folding for the Eurocube. The capacity of the mixers can be of various types, sizes, materials (steel, stainless steel, plastic, etc.).

Production of mixers— this is the main, however, is not the only way to develop the company. We are engaged in the design of technological lines, equipping the production with equipment taking into account factors, installing heat exchangers, reflecting partitions, etc.

Mechanical mixing devices

mixers (mechanical) are used almost everywhere — from household enterprises to oil refineries, and have the following purpose:

- acceleration of chemical processes in mixed components;

- mixing solids in liquids;

- increased intensity of heating or cooling;

- maintaining the set temperature of the mixture.

Mixers the set includes components:

- Actuallya mixer (impeller)— a working element of the device.

- A shaft located in a machine or container at a certain angle.

- Drive. Most often — an electric motor, a gear motor, for more powerful mixers — DVS.

As a rule, large industrial mixers, which are offered with containers, are arranged vertically. Small mixers are installed, according to the mixing technology in the manufacture of solutions. Among them there are types of mixers , which are installed horizontally ( horizontal mixer ). They are also called lateral.

Mixers differ not only in design features, but also in the created fluid flow, but more on that later.

Here are the main types of mixers and their characteristics.

Devices with a top — drive mixer

Our company performs manufacture of mixers vertical type — vertical mixers with top drive. Among them are:

- Frame and anchor mixers — low-speed type of devices that are used in almost all industrial sectors. The diameter of the mixer itself is almost equal to the diameter of the vessel in which the mixing is carried out. This design allows you to perform mixing efficiently, without leaving a residue even in a viscous medium. In addition, anchor mixers prevent the overheating of the liquid, which often accompanies the mixing process. Sometimes the anchor mixer needs additional transverse elements, which turns it into a frame mixer. This is necessary when the anchor structure cannot cope with a high viscosity fluid.

- The paddle mixer is characterized by high speed. Structurally, the mixer is equipped with two blades located one above the other and having a rectangular section. This design is used to prepare liquids with different densities, the liquid forming the precipitate, as well as to dissolve solid components. Most often, paddle mixers are used in chemical industries, or in industries where similar mixing processes are provided for by technologies.

- Turbine mixer — high-speedmixer for liquidshigh viscosity. Since the turbine mixer operates on the principle of a centrifugal pump, it can in some cases push the stirred suspension out of the tank, it can either be open or closed. The mixer is equipped with small blades, which create radial flows, providing accelerated circulation of the liquid and its high-quality mixing. It is relevant for the production of viscous and liquid suspensions used in the chemical, pharmaceutical, food industry.

- Milling mixer — high-speed type. Structurally, the mixer is an impeller, similar to a disk, equipped with blades in the form of teeth. A milling mixer can be attributed to universal devices, because it can be etched not only by mixing liquids of various viscosities, but also by grinding solid components, both separately and as part of a multicomponent liquid. The versatility of the milling mixer allows it to be in demand in most industries of the domestic industry.

- Propeller mixer — high-speed type. The mixer is made, depending on the model, in the form of a propeller with two, three and four blades. The blades are curved screw-like, which makes possible not only rotational mixing of the liquid, but also mixing along the vertical axis. Such mixers are used where processes require the creation of low-viscosity liquids — emulsions, thin suspensions. The design of the mixer allows the component to circulate even with minimal power and mechanical energy.

- Folding mixers for the Eurocube are a kind of modified paddle or propeller mixers. A distinctive feature is that they are located inside a cubic container made of plastic called a Eurocube. The neck of the container has a small diameter. A cross with blades is fixed on the shaft, which in a resting position are naturally folded. As a result, the folded blades are quite convenient to lower into a Eurocube even through a narrow neck. Then, when the drive is turned on, the blades acquire a working horizontal position under the action of inertia. It is in this position that the folding mixer becomes an analogue of a paddle or propeller.

- The conical mixer applies to both high-speed and slow-moving mixers and serves to mix a variety of substances. Unlike other high-speed mixers of this type such as milling, turbine, propeller, conical mixers due to the forms of the impeller creates a dynamic radial flow, which allows to turn any substances into a homogeneous mixture in a short time and with little energy consumption.

You can order all this equipment for mixing from us. We make all devices with a measuring device according to individual drawings.

Mixing equipment

- Frame and anchor mixers

- Paddle mixers

- Turbine mixers

- Milling mixers

- Propeller mixers

- Folding mixers for a Eurocube

- Conical mixers

I would like to pay special attention tocontainers in whichis mixed.

They are performed of different types, sizes, among them:

- Steel tanks made of carbon steel;

- Stainless steel tanks, the bottom can be flat, spherical or conical;

- Plastic cubic containers called Eurocube.

Reflectors and heat exchangers can be installed in mixing tanks. Among other things, theapparatus with a mixercan be made, according to the drawings of the customer, if the production technology provides for dimensions and design of a mixer that are different from the standard ones. For this we performcalculation of mixers.

A mixer drive is also selected depending on the requirements for power and speed, which can also be voiced by the customer.

You can order any equipment with a mixing function from us.

The Customs Union. Declarations of conformity.

Industrial equipment manufactured byTula Mashiny crushing equipment factorycomplies with the requirements of the Technical Regulations and the Customs Union: TR CU 010/2011 “On the safety of machinery and equipment; TR TS 004/2011 “On the safety of low-voltage equipment” TR TS 020/2011 “Electromagnetic compatibility of technical equipment”.